Lightweight yet powerful, the binocular inverted metallurgical microscope distributer continues to raise the standard for efficiency of operation. High-performance control algorithms provide instant acceleration and smooth deceleration, protecting delicate samples from stress. Dual cooling systems provide thermal stability in even long runs. Modular design provides easy maintenance and upgrading. Remote diagnostics and system optimization connectivity is available in some models. Along with these advancements, the binocular inverted metallurgical microscope distributer becomes a bridge between traditional engineering and modern automation and functions as a pillar of accurate, high-rate separation within labs and factories around the world.

The versatility of binocular inverted metallurgical microscope distributer can be seen in its application to numerous specialized fields. In marine biology, it helps one analyze plankton and microbial samples. In food science, it helps with the accurate measurement of fat and protein content. The electronics sector employs binocular inverted metallurgical microscope distributer for purifying liquid crystals and conductive materials. In environmental protection, binocular inverted metallurgical microscope distributer facilitate tracking of pollutants and studies on recycling. They aid in veterinary medicine in blood diagnosis and disease investigation. With these uses, binocular inverted metallurgical microscope distributer bring about innovation through offering dependable means for analyzing as well as separating materials.

{Keywords} of the future will unprecedentedly advance in performance and design. Future systems will feature adaptive balancing technology that adjusts to dynamic loads in real time. Intelligent rotors will track stress and fatigue in real time, allowing for extended service life. With IoT connectivity, multiple binocular inverted metallurgical microscope distributer units will be remotely managed to streamline laboratory networks. In biomedical applications, miniaturized devices will facilitate high-throughput screening with low sample volumes. These advancements are a step toward smarter, faster, and greener devices that revolutionize how separation processes are controlled in modern science.

Maintenance procedure routines protect the performance and safety of binocular inverted metallurgical microscope distributer. The rotor needs to be visually inspected before each operation for cracks or corrosion. Mild detergents are needed for cleaning, followed by thorough drying to prevent rust. Calibration verification and vibration monitoring assist in keeping it accurate. The instrument should be set on a level surface to reduce stress on bearings. During storage, binocular inverted metallurgical microscope distributer must be kept covered and not plugged to keep electronics safe. Under operator discipline and regular maintenance, laboratories can offer years of trouble-free performance.

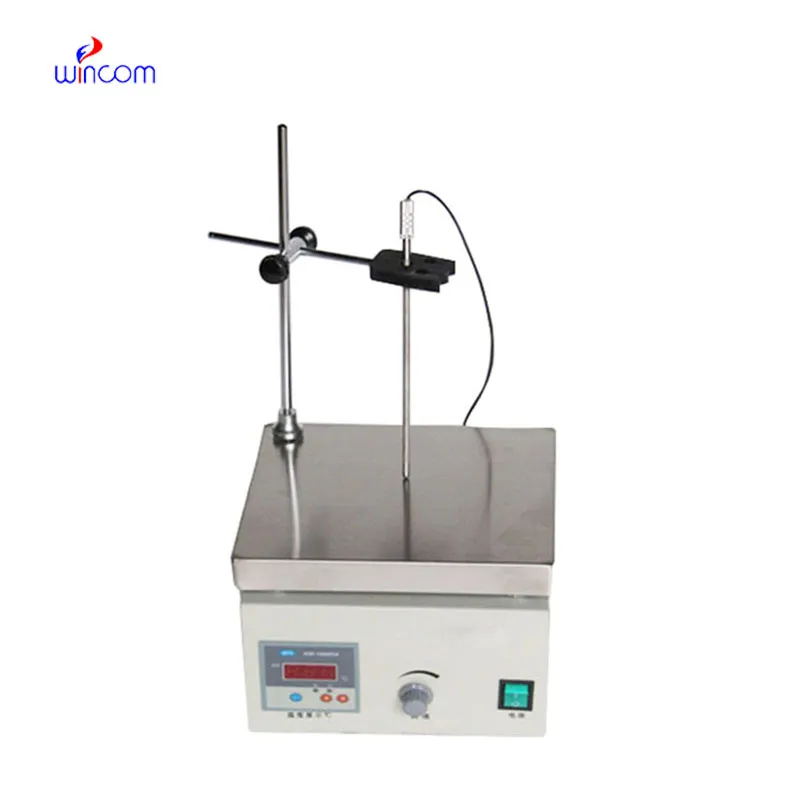

Scientific and industrial applications use the binocular inverted metallurgical microscope distributer for its ability to differentiate between mixes with high precision. It relies on the force of centrifugal, which pushes particles off center, leading to density stratification. The method is vital in research, medicine, and engineering. From cell constituents separation to the separation of liquids, binocular inverted metallurgical microscope distributer make many analytical and production processes easier. Newer models focus on minimizing vibration, maximizing balance, and the use of smart sensors to monitor data in real time. All these advancements have made binocular inverted metallurgical microscope distributer faster, safer, and more efficient than before.

Q: How is a centrifuge different from a mixer or shaker? A: Unlike mixers or shakers that blend materials, a centrifuge separates components based on density through high-speed rotation. Q: What power requirements does a centrifuge need? A: Most benchtop centrifuges use standard AC power, while industrial units may require higher voltage for greater speed and capacity. Q: Can a centrifuge be used in pharmaceutical production? A: Yes, centrifuge equipment is widely used to purify chemical compounds and biological materials during drug manufacturing processes. Q: How do I prevent vibration during operation? A: Ensure all tubes are evenly loaded, rotors are clean, and the machine is placed on a stable, level surface. Q: What is the lifespan of a centrifuge? A: With regular maintenance and proper usage, a centrifuge can last for many years while maintaining consistent performance.

We’ve used this centrifuge for several months now, and it has performed consistently well. The speed control and balance are excellent.

We’ve been using this mri machine for several months, and the image clarity is excellent. It’s reliable and easy for our team to operate.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you please provide more information about your microscope range? I’d like to know the magnif...

We’re looking for a reliable centrifuge for clinical testing. Can you share the technical specific...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China