The function of a centrifugal force ap hug structure depends entirely on its integrity. Manufacturers now use advanced dynamic balancing techniques to minimize vibration and increase lifespan. High-torque motors give smooth rotational power, and safeguards such as locking lids and imbalance sensors protect the user and sample from injury. In specialized lab arrangements, refrigerated centrifugal force ap hug maintain constant temperatures for biological samples. Miniaturized forms are also gaining ground, sacrificing space savings for speed and accuracy. These trends show the ongoing coming of age of centrifugal force ap hug engineering into versatility and reliability.

From research in the laboratory to large-scale production, centrifugal force ap hug devices have a place in processes requiring precision and efficiency. They purify reaction mixtures and solvents in chemical production. Hospitals rely on centrifugal force ap hug for the testing of patients and therapeutic treatment. In farming, centrifugal force ap hug are used to study plant biology and develop fertilizer formulations. In brewing and winery operations, they provide consistency within products by filtering out impurities. Even environmental engineers rely on centrifugal force ap hug to filter sediment as well as identify contaminants. Such wide-ranging functionality demonstrates its vital position in contemporary technology and applied sciences.

The centrifugal force ap hug of the future will be innovative, intelligent, and integrated. With the advent of smart manufacturing, centrifugal force ap hug systems will operate independently on predictive analytics. Programs with machine learning will interpret vibration patterns to optimize performance with minimal human involvement. Renewable energy integration will make operation more sustainable, and modular design will facilitate instant replacement of parts. Data visualization software will be more sophisticated, providing real-time feedback on the separation process. This blend of mechanical precision and intelligent technology will place centrifugal force ap hug at the forefront of international scientific advancement.

Continuous cleaning and routine checkup maintain a centrifugal force ap hug in good working order. The rotor must be carefully inspected for distortion or corrosion because even small flaws can result in unbalance. Users should clean the interior chamber with a soft cloth at the end of each run to remove residues. Electrical and mechanical components must undergo regular checks for proper alignment and accuracy of speed. Periodic calibration at specified intervals maintains measurement precision. By implementing a formal maintenance regime and strict compliance with manufacturer instructions, the centrifugal force ap hug is dependable upon repetitive application.

Scientific and industrial applications use the centrifugal force ap hug for its ability to differentiate between mixes with high precision. It relies on the force of centrifugal, which pushes particles off center, leading to density stratification. The method is vital in research, medicine, and engineering. From cell constituents separation to the separation of liquids, centrifugal force ap hug make many analytical and production processes easier. Newer models focus on minimizing vibration, maximizing balance, and the use of smart sensors to monitor data in real time. All these advancements have made centrifugal force ap hug faster, safer, and more efficient than before.

Q: How is a centrifuge different from a mixer or shaker? A: Unlike mixers or shakers that blend materials, a centrifuge separates components based on density through high-speed rotation. Q: What power requirements does a centrifuge need? A: Most benchtop centrifuges use standard AC power, while industrial units may require higher voltage for greater speed and capacity. Q: Can a centrifuge be used in pharmaceutical production? A: Yes, centrifuge equipment is widely used to purify chemical compounds and biological materials during drug manufacturing processes. Q: How do I prevent vibration during operation? A: Ensure all tubes are evenly loaded, rotors are clean, and the machine is placed on a stable, level surface. Q: What is the lifespan of a centrifuge? A: With regular maintenance and proper usage, a centrifuge can last for many years while maintaining consistent performance.

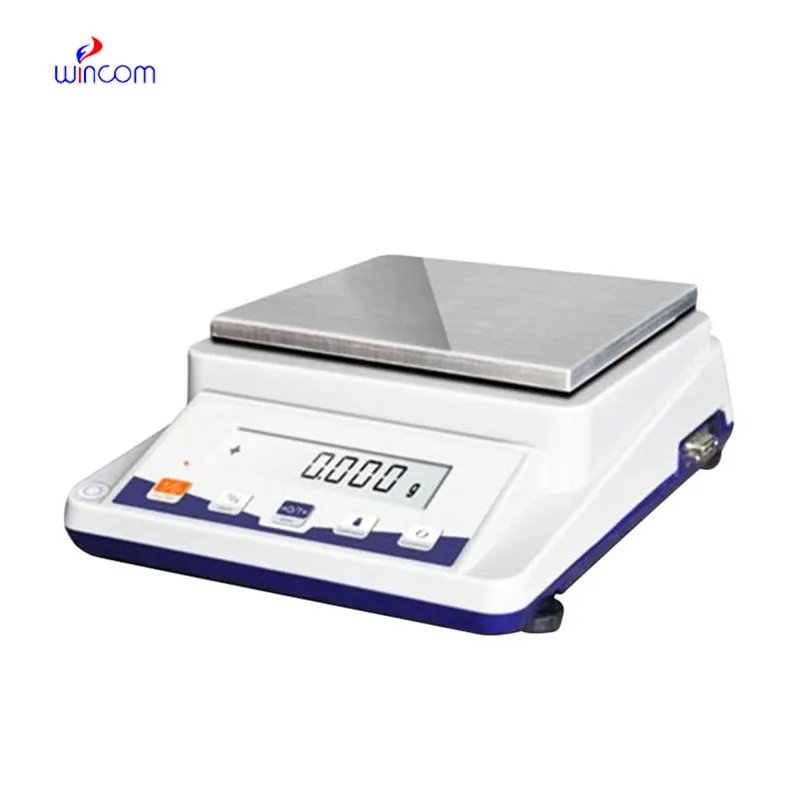

The centrifuge operates quietly and efficiently. It’s compact but surprisingly powerful, making it perfect for daily lab use.

The water bath performs consistently and maintains a stable temperature even during long experiments. It’s reliable and easy to operate.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you please provide more information about your microscope range? I’d like to know the magnif...

Hello, I’m interested in your water bath for laboratory applications. Can you confirm the temperat...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China